CEO Msg

ATI Japan Corp.

Representative Director Masahiro Kawasaki

ATI Japan Corp.,

centered on world-class ultra-thick thermal oxide film manufacturing technology, provides solutions that support the future of the optical communication and semiconductor industries.

Our proprietary ultra-thick thermal oxide film manufacturing technology achieves unparalleled thickness and high quality, earning high praise from domestic and international customers.

Currently, the optical communication and semiconductor industries are becoming increasingly important as the core of next-generation industries such as data centers, AI, and electric vehicles.

Through the most advanced film deposition process, our company is committed to enhancing the performance and reliability of critical devices supporting these industries.

At the same time, we are expanding our view from Japan to the world, collaborating with international partners to deepen R&D and manufacturing technology.

We firmly believe in the maxims of "being sincere about technology," "seriously engaging with customers," and "pursuing ultimate quality," and we aim to be a company that continuously takes on challenges.

We kindly ask for your continued support and guidance to ATI Japan.

Biography of Representative Director Masahiro Kawasaki

Career of Masahiro Kawasaki, Representative Director

May 1998 Established KST World Co., Ltd. in Fukui City, Fukui Prefecture.

March 1999 Established Kawasaki Semiconductor Technology America Corp. (KST America).

Opened offices in California and Arizona. Served as CEO.

January 2013 Established Kawasaki Semiconductor Technology Taiwan Corp. (KST Taiwan).

Opened office in Kaohsiung City. Served as Chairman.

Kawasaki Semiconductor Technology Taiwan Corp.

January 2022 Stepped down as Representative Director and President of Seiren KST Co., Ltd.

March 2022 Established ATI Japan Corp.

Corporate Philosophy

■ Mission

To change the world of optical communication and semiconductors with the world's highest-level ultra-thick thermal oxide film manufacturing technology.

ATI Japan contributes to the advancement and reliability improvement of the optical communication and semiconductor industries through its ultra-thick thermal oxide film manufacturing technology. We strive to realize a sustainable affluent society through creativity and realization capability.

■ Vision

To become a globally recognized technical brand where "ATI Japan is synonymous with ultra-thick thermal oxide film."

Our goal is to continuously maintain world leadership in quality, performance, and technological innovation, and to be the company of choice for customers and the industry.

■ Values

The values we cherish:

Sincerity and Trust

Always maintain a sincere attitude toward both technology and people.

Challenge Technological Innovation

Not satisfied with the status quo, continuously challenge the limits of processes and equipment.

Quality First Principle

Pursue uncompromising quality in a world demanding nano-level precision.

Customer-Centric Manufacturing

Listen to customer voices and walk the path of solving challenges together.

Global Perspective

Deliver technology originating in Japan to the world and create international value.

Quality Policy / Environmental Commitment

■ Quality Policy

ATI Japan Corp. shall always provide quality that meets customer expectations through the world's top ultra-thick thermal oxide film manufacturing technology.

We commit to quality improvement company-wide based on the following fundamental policies for quality activities:

・Uncompromising quality principle pursuing nano-level precision

・Continuous improvement starting from customer feedback

・Thorough standardization and visualization of processes, equipment, and materials

・Operation and continuous improvement of the Quality Management System (QMS)

・Providing trust through simultaneous pursuit of quality and safety

■ Environmental Commitment

ATI Japan Corp. recognizes global environmental protection as a vital corporate responsibility and promotes the development and operation of clean and sustainable film deposition technology.

We will implement the following environmental actions:

・Development and introduction of energy-saving and resource-conserving film deposition technology

・Thorough waste reduction, sorting, and recycling

・Compliance with environmental laws/regulations and transparent disclosure of information

・Raising environmental awareness among all employees and practicing action

・Promotion of corporate activities aimed at realizing a sustainable society

Company Overview

ATI Japan Corp.

• Company Name : ATI Japan Corp. (Japanese: ATI Japan 株式会社)

• Date of Establishment : March 18, 2022

• Representative Director : Masahiro Kawasaki

• Head Office Address : 3-16-14 Nishishinagawa, Shinagawa-ku, Tokyo

• Nihonbashi Office : JACC Building 4F, 2-8-5 Nihonbashi Horidome-cho, Chuo-ku, Tokyo

• Capital : 96.55 million JPY, Capital Reserve: 96.55 million JPY

• Main Banks : Mizuho Bank Shibuya Chuo Branch, MUFG Bank Nihonbashi Branch

• Secondhand Dealer License : Tokyo Metropolitan Public Safety Commission Permit No. 301042422058

• Invoice Number : T4010001225392

• Associations etc. : Japan-China Economic Association Supporting Member,

MEMS Park Consortium Member

• Business Partners :

Company History

History of ATI Japan Corp.

March 2022: Established in Chuo-ku, Tokyo

May 2023: Relocated to Shinagawa-ku, Tokyo

October 2024: Opened "Nihonbashi Office" in Nihonbashi Horidome-cho, Chuo-ku, Tokyo

March 2025: Established ATIJ Hong Kong Limited

Executives

Board Members

- Representative Director (CEO): Masahiro Kawasaki

- Director: Enyo O

- Director: Tetsuya Naito

- Director: Masamitsu Yoshizawa

- Auditor: Yoshikazu Kamiya

Representative Director (CEO)

Masahiro Kawasaki

|

Director

Enyo O

|

Director

Tetsuya Naito

|

Director

Masamitsu Yoshizawa

|

Advisors

Masayoshi Esashi

Masayoshi Esashi:

CTO, MEMS Core Co., Ltd.

Concurrent Senior Research Fellow, Tohoku University

2022 - Order of the Sacred Treasure, Gold and Silver Star

|

Ryutaro Maeda

Ryutaro Maeda:

National Institute of Advanced Industrial Science and Technology (AIST)

Emeritus Researcher, Device Technology Research Institute

Distinguished Professor, School of Instrument Science and Engineering, Xi'an Jiaotong University

|

Takunori Taira

Takunori Taira:

Group Director, RIKEN SPring-8 Center

Specially Appointed Professor, Institute for Molecular Science, National Institutes of Natural Sciences

OPTICA (OSA), SPIE, IEEE Fellow

|

Fumiyuki Ota

Fumiyuki Ota:

Former General Manager, Toshiba Oita Plant, Former Vice President, Dominion Semiconductor,

Former President, Tokuyama Toshiba Ceramics, Former Director, KST World

|

Nobuhiko Sasaki

Nobuhiko Sasaki:

Chairman, Japan-China Economic Association, 13th President, Japan External Trade Organization (JETRO)

Former Counselor, OECD Mission, Ministry of Foreign Affairs, Vice-Minister for International Affairs, METI,

Director General, JETRO Beijing Center, etc.

|

Access Map

Head Office

〒141-0033

3-16-14 Nishishinagawa, Shinagawa-ku, Tokyo

Nihonbashi Office

〒103-0012

JACC Building 4F, 2-8-5 Nihonbashi Horidome-cho, Chuo-ku, Tokyo

(📍View Address on Google Maps)

Tel: 03-6661-2251 Fax: 03-6661-2252

5-minute walk from Ningyocho Station (Tokyo Metro Hibiya Line / Toei Asakusa Line)

8-minute walk from Bakurocho Station (JR Sobu Line Rapid)

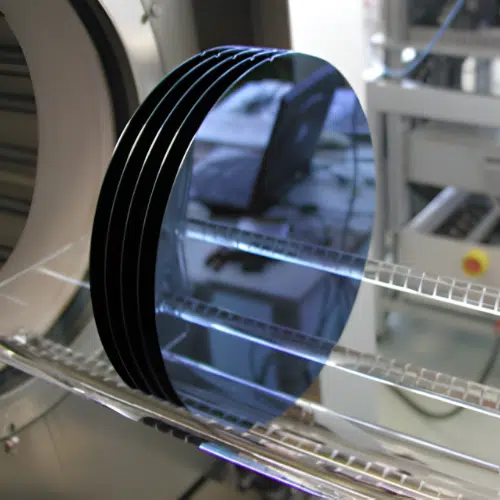

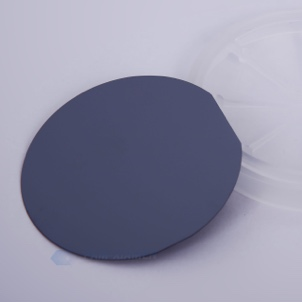

Silicon Wafers

・Sizes: 4 inch (100mm) to 12 inch (300mm)

・Crystal Growth Method: FZ (Float Zone) (>5,000Ω・cm, >10,000Ω・cm)

CZ (Czochralski)

MCZ (Magnetic Czochralski)

・Manufacturers: Japanese, US, Taiwanese, Korean, Chinese, European

・Prime Wafer, Test Wafer, Monitor Wafer, Dummy Wafer, Reclaimed Wafer

※For quotes, inquiries, etc., please contact us here

Example Wafer Specifications Handled

Silicon Wafer

Crystal Growth

Method |

Conductivity

Type |

Dopant |

Crystal

Orientation |

Resistivity |

Oxygen

Content |

Carbon

Content |

Diameter |

Primary Flat

Location |

Primary Flat

Length |

Thickness |

Front Surface |

Back Surface |

| FZ |

P |

Boron |

<100> ± 1

degree |

10,000–99,999

Ω-cm |

0.4 ppma |

0.4 ppma |

150 ± 0.5mm |

<110> ± 2

degrees |

57.5 ± 2.5mm |

675 ± 10 um |

Polished |

Etched |

| CZ |

P |

Boron |

<100> ± 1

degree |

1~20 |

1~50 |

1~50 |

200 ± 0.2mm |

<011> ± 1

degree |

57.5 ± 2.5mm |

725 ± 15 um |

Polished |

Etched |

| MCZ |

P |

Boron |

<100> ± 1

degree |

0.5~100.00 |

- |

- |

300 ± 0.2mm |

Notch |

Notch |

760 ~ 790 um |

Polished |

Polished |

Wafer Basic Knowledge

| Grade |

Primary Use |

Quality Level |

Characteristics |

Cost Perception |

| Prime Grade |

Actual Device Manufacturing (IC, Power Devices, MEMS, etc.) |

Highest |

・Surface roughness, defect density, particles are strictly controlled

・Most stable electrical properties and crystal defects

|

High |

| Monitor Grade |

Process Monitoring in Mass Production Lines |

High

(Close to Prime) |

・Supplied with the same crystal orientation, conductivity type, and resistivity as product wafers

・Defect tolerance is looser than Prime・Performance and quality are equivalent to Prime during the process

|

Medium

(Cheaper than Prime) |

| Test Grade |

Equipment Startup, Trial Processing, Research Applications |

Medium |

・Allows surface defects and micro-scratches・Electrical properties are not emphasized

・Reproducibility of product performance is not as strictly required as Monitor

|

Relatively Cheap |

| Dummy Grade |

Handling Practice, Equipment Calibration, Physical Practice |

Low |

・Allowed to contain more cracks and defects

・Conductivity type, resistivity, etc., are usually not specified

・Essentially treated as a "silicon disc"

|

Cheapest |

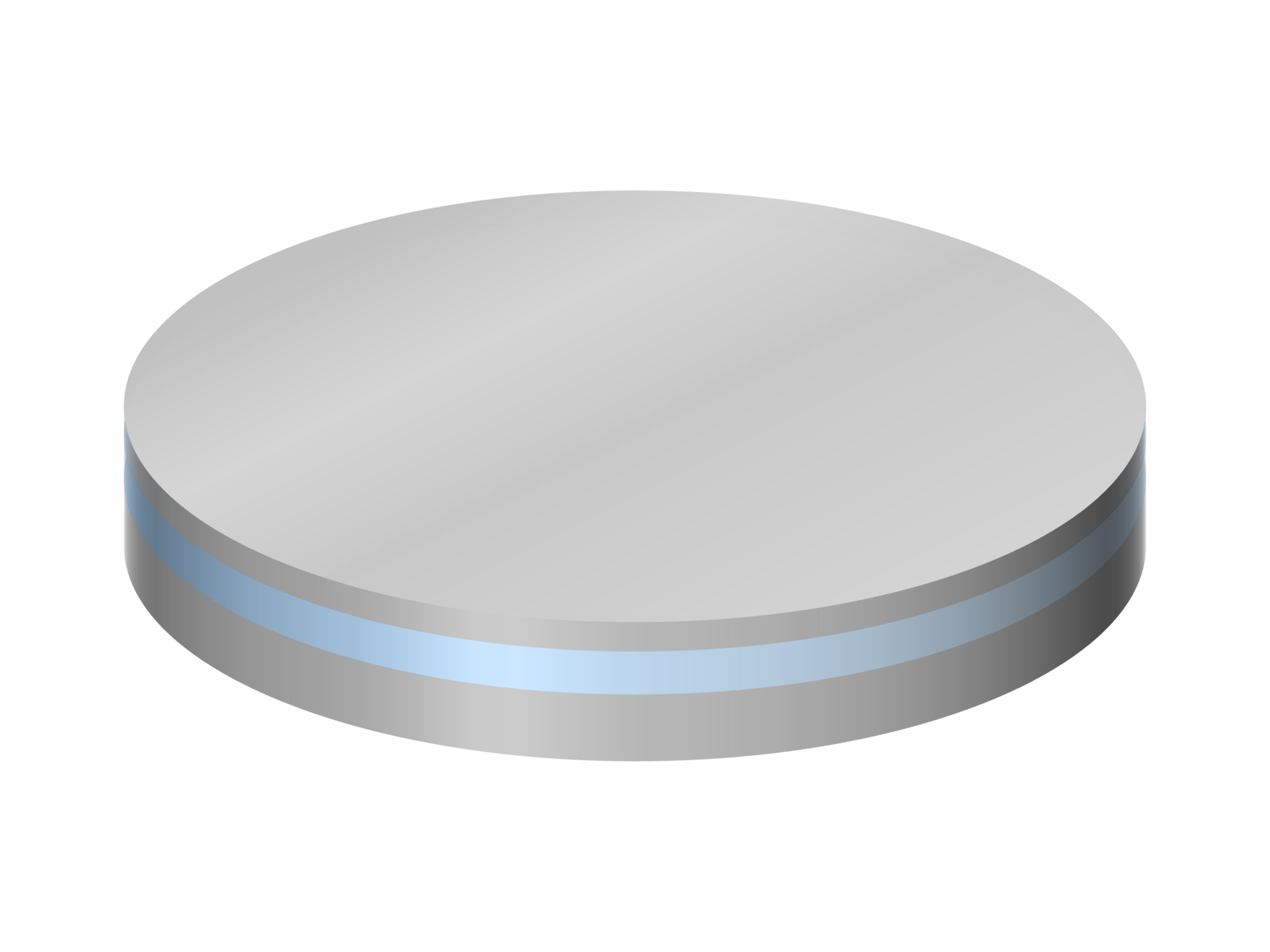

Ultra-Thick Film to Thin Film Thermal Oxide Wafers

ATI Japan uses the thermal oxidation method to deposit ultra-thick films. This achieves film quality unattainable with the CVD method.

Currently, we can handle film deposition in the range of 2µm to 20µm, which is considered difficult with the thermal oxidation method.

Wafer diameters supported are 6 inch (150mm), 8 inch (200mm), and 12 inch (300mm).

Thick films are widely used in optical communication, MEMS, medical, power devices, and other fields.

Thin films can be used for testing, evaluation, development, and other purposes.

※For quotes, inquiries, etc., please contact us here

InP Wafers

InP (Indium Phosphide) Wafers・・・Official Japan Agent for Grenoble InPACT, France

Indium Phosphide manufacturer covering all dopants (Fe, Sn, Zn, S) and

all diameters (2", 3", 4")

Properties: High-efficiency semiconductor for high-frequency communication and optical communication.

Applications: Lasers, optical amplifiers, optical fibers for optical communication, etc.

Features: Possesses high electron mobility and high dielectric breakdown strength.

※For quotes, inquiries, etc., please contact us here

Thin Film SOI Wafers, Thick Film SOI Wafers, Bonded Wafers

・SOI (Silicon-on-Insulator)

ATI Japan offers SOI wafers of various specifications.

For small volumes and short lead times, you can choose from our stock SOI wafers.

Stock SOI wafers are available starting from one piece.

・Excellent Device Layer Uniformity (±0.1µm)

・Low Stress Close to Single Crystal Wafer

・Extremely Small Steps (0.5㎜)

・Extremely Thin Substrate Wafer (50µm~)

・POI Wafers, and other bonded wafers

・POI (Polymer-on-Insulator)

・SiC on Si

・GaN on Si

・Others

Please feel free to contact us regarding bonded wafers.

※For quotes, inquiries, etc., please contact us here

Semiconductor Related Parts

・O-ring

Official Japan agent for KT Seal, Taiwan, providing perfluoroelastomer O-rings with excellent chemical and plasma resistance.

Stable supply of O-rings officially adopted by TSMC and UMC.

※For quotes, inquiries, etc., please contact us here

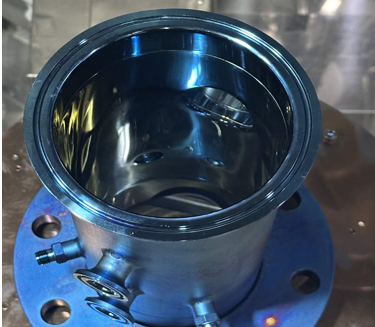

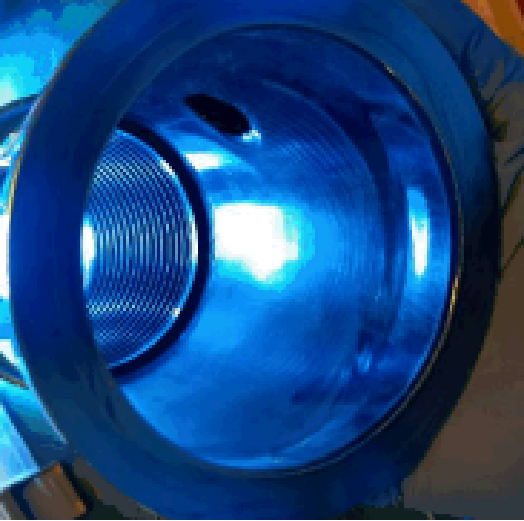

Semiconductor Related Parts

・Piping AF (Anti-Fouling) Coating

Properties (Corrosion resistance, abrasion resistance)

Complex piping can be processed using Wet Coating

※For quotes, inquiries, etc., please contact us here

GPU Server

We handle products from the world's top server manufacturers.

※For quotes, inquiries, etc., please contact us here

Optical Components

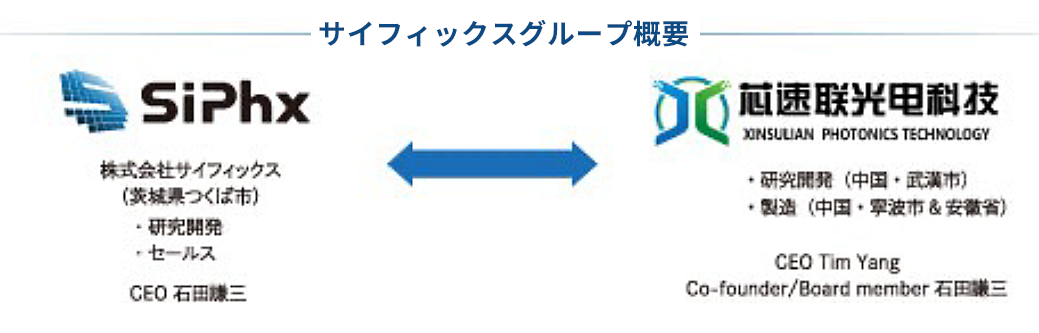

Official agent for SiPhx optical modules.

1.6T, 800G, 400G Optical Transceivers

※To PDF

※For quotes, inquiries, etc., please contact us here

MEMS Consulting

We provide consulting services for foundries, personnel, patents, etc.

※For quotes, inquiries, etc., please contact us here

Work

Adipiscing magna sed dolor elit. Praesent eleifend dignissim arcu, at eleifend sapien imperdiet ac.

Aliquam erat volutpat. Praesent urna nisi, fringila lorem et vehicula lacinia quam. Integer

sollicitudin mauris nec lorem luctus ultrices.

Nullam et orci eu lorem consequat tincidunt vivamus et sagittis libero. Mauris aliquet magna magna

sed nunc rhoncus pharetra. Pellentesque condimentum sem. In efficitur ligula tate urna. Maecenas

laoreet massa vel lacinia pellentesque lorem ipsum dolor. Nullam et orci eu lorem consequat

tincidunt. Vivamus et sagittis libero. Mauris aliquet magna magna sed nunc rhoncus amet feugiat

tempus.

About

Lorem ipsum dolor sit amet, consectetur et adipiscing elit. Praesent eleifend dignissim arcu, at

eleifend sapien imperdiet ac. Aliquam erat volutpat. Praesent urna nisi, fringila lorem et vehicula

la

lacinia quam. Integer sollicitudin mauris nec lorem luctus ultrices. Aliquam libero et malesuada

fames ac ante ipsum primis in faucibus. Cras viverra ligula sit amet ex mollis mattis lorem ipsum

dolor sit amet.

Contact

Inquiry

Sending completed!